One more: “Suck it up, Buttercup” post.

A brief lesson on skills, shortcuts, experience, efficiency. (As usual?)

Leather skiving. Essentially, thinning leather. Don’t confuse this with leather splitting. Which is sort of the same.

“Splitting” is thinning an entire leather piece (or hide) to one continuous and hopefully consistent thickness. Example, going from 10 oz to 6 oz.

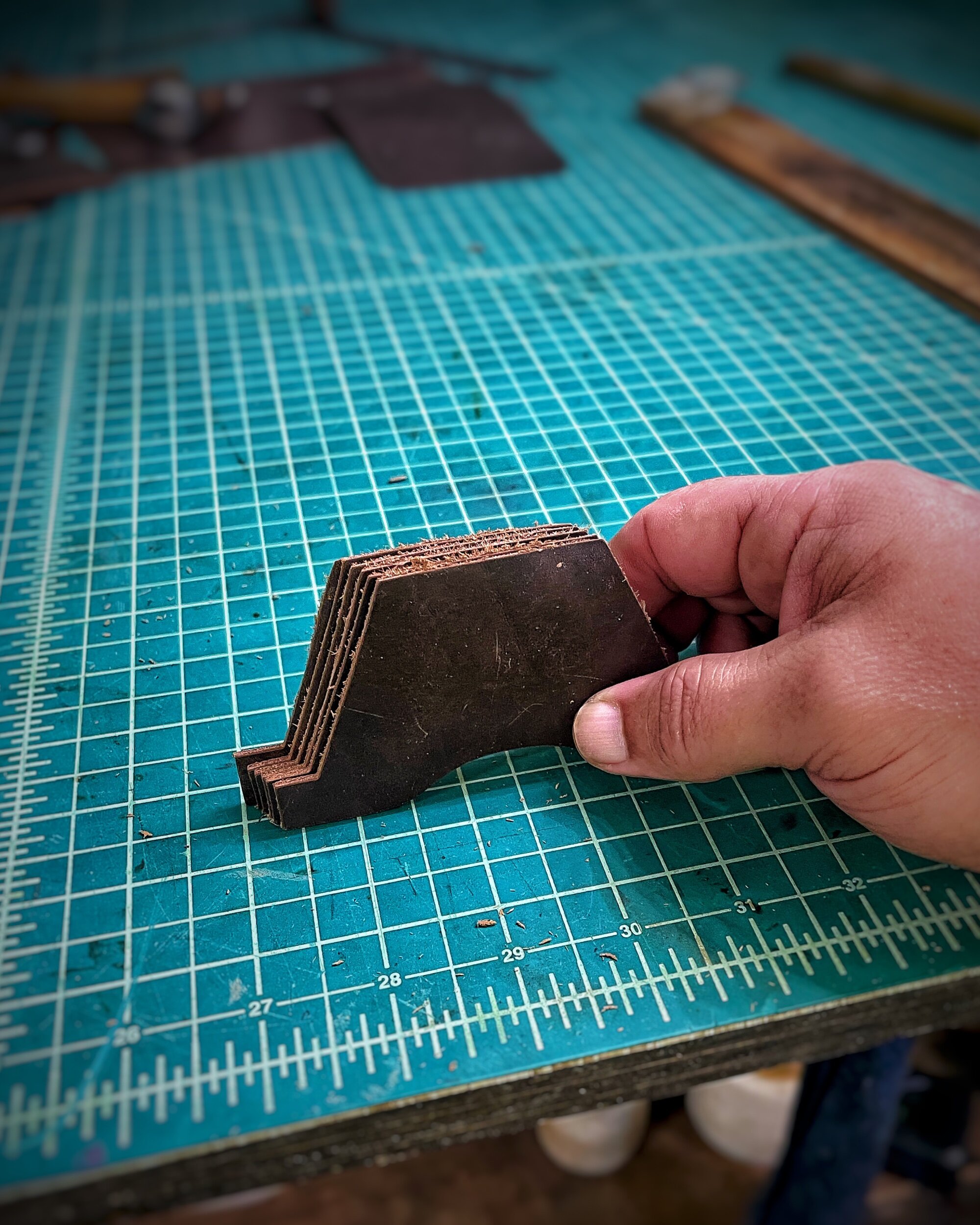

“Skiving” thins, as well. But usually it’s only a section of the leather piece. Usually a gradual slope sliced off. Example, from 10 oz on one end down to 2 oz to the other. Think of a wedge.

Skiving is good for when folding over a top hem (to keep thinner after folded) or the bottom of stacked “T” pockets (as seen in this post). I’ve shown both of these examples in various videos on my YouTube channel.

Now the “Buttercup” part:

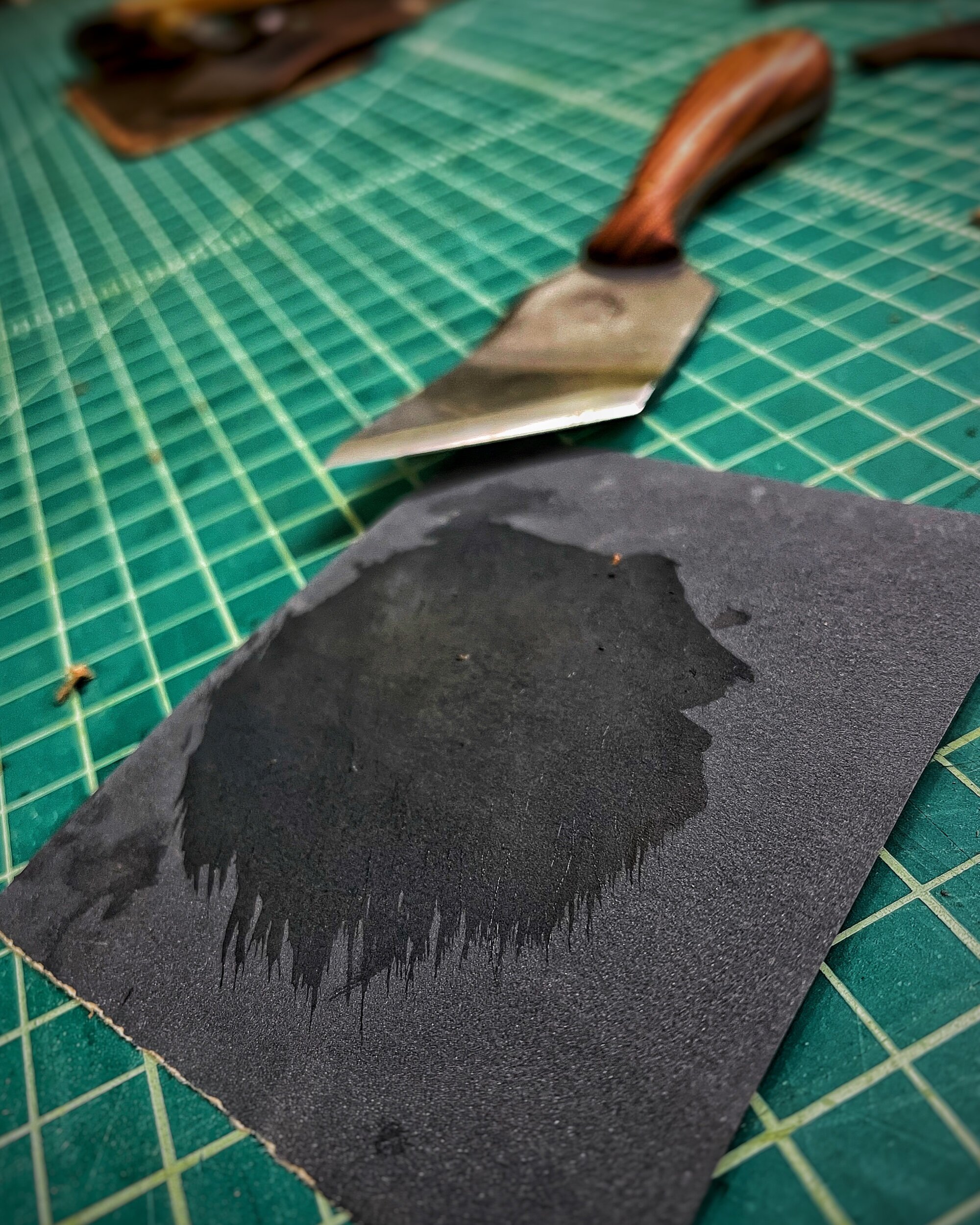

I’ve skived leather by hands for many years. And it’s definitely an art form to get right and perfect. Also, requires an ideal knife and sharp blade. (See @ibexironworks - custom made, custom angle bent, backasswards to my backasswards method)

They say (Malcom Gladwell?) it takes 10,000 hours to master a skill. Well, I’ve done it. I’m there.

Skiving for the first few years was a hugely dreaded affair for me. Slammed full with frustration and aching hands. I’ve gotten now, to where it’s effortless. Again, knife, angle, sharp, strop, etc.

See here how the skiving can be done with extreme precision after those 10,000 hours. Large pieces removed are a good indication of this.

(Note: You see 1000 grit sand paper here. 2000+ would be better, but I didn’t feel like going out to the forge to get it.)

As a result, I’m now aiming toward more efficiency.

On the way is a bell skiver. Thanks to @leather_machine_co

Stay tuned for future updates!!

Red Imp, cordovan strop. The “c” in “700C” stands for the cordovan variety.

#Leather #leathercraft #leatherwork #leatherwork #leatherwallet #leathercrafter #leatherworker #leatherlove #leatherdesign #leatherdiy #leatherlove

![IMG_9905[1].jpg](https://images.squarespace-cdn.com/content/v1/5425c66fe4b0d373ae2c6cba/1602250964827-MJBX0JM1JN1KSMO5E3RR/IMG_9905%5B1%5D.jpg)

![IMG_9914[1].jpg](https://images.squarespace-cdn.com/content/v1/5425c66fe4b0d373ae2c6cba/1602250965362-G1NH1H88K0TB2I3K11MF/IMG_9914%5B1%5D.jpg)

![IMG_8649[2].jpg](https://images.squarespace-cdn.com/content/v1/5425c66fe4b0d373ae2c6cba/1602250961513-AJ025IYLWBNAXRQQ3WSX/IMG_8649%5B2%5D.jpg)

![FullSizeRender[2].jpg](https://images.squarespace-cdn.com/content/v1/5425c66fe4b0d373ae2c6cba/1602250960700-ZLQ1HW6TL7PRUPOCU7Q2/FullSizeRender%5B2%5D.jpg)

![FullSizeRender[4].jpg](https://images.squarespace-cdn.com/content/v1/5425c66fe4b0d373ae2c6cba/1602250960725-AE2Q9LOQ34FLWP57MFKG/FullSizeRender%5B4%5D.jpg)

![IMG_9893[2].jpg](https://images.squarespace-cdn.com/content/v1/5425c66fe4b0d373ae2c6cba/1602250962889-DUJHP0ZN3CLB69E6EH50/IMG_9893%5B2%5D.jpg)

![IMG_9892[2].jpg](https://images.squarespace-cdn.com/content/v1/5425c66fe4b0d373ae2c6cba/1602250962356-MRRHWKNZFXYBQ4AB6ZKS/IMG_9892%5B2%5D.jpg)

![IMG_9894[1].jpg](https://images.squarespace-cdn.com/content/v1/5425c66fe4b0d373ae2c6cba/1602250964167-JF4LP7GHUO74MQJMWW73/IMG_9894%5B1%5D.jpg)

![IMG_9125[2].jpg](https://images.squarespace-cdn.com/content/v1/5425c66fe4b0d373ae2c6cba/1602250961813-RNTMIU73ETHBZ9IIM1KA/IMG_9125%5B2%5D.jpg)